Njikọ, nke a makwaara dị ka nkụnye eji isi mee ma ọ bụ wafer, bụ njikọ nke na-anọdụ n'elu bọọdụ sekit e biri ebi ma dị mkpa ka erere ya na ntụtụ sekit.

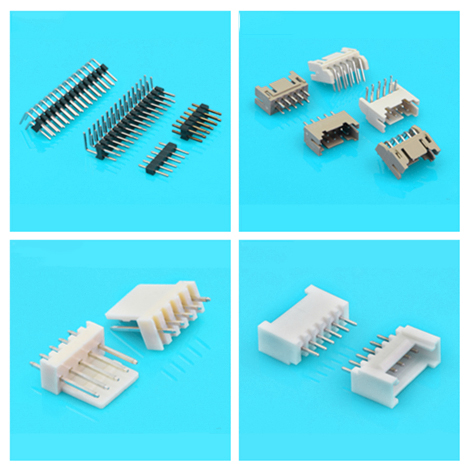

Ihe njide ntụtụ a na-ahụkarị bụ: enweghị ntọala mkpuchi (dịka ọmụmaatụ: nhazi agịga ahịrị), ntọala mkpuchi (ụdị wafer a na-ahụkarị), ụdị mkpọchi esemokwu.

Ihe njide ntụtụ nke njikọ bụ nke rọba pụrụ iche maka ọnọdụ okpomọkụ dị elu, ọ dịkwa mkpa inwe nguzogide okpomọkụ dị elu.Dịka ọmụmaatụ, ihe njide agịga a na-eji maka ịgbado ọkụ n'elu elu ga-ejikọta ya site na ngwa ịgbado ọkụ reflow, na okpomọkụ ga-eru ihe dịka 265 °;Nke ọzọ bụ na ụdị ntụtụ kwesịrị ka welded site na ife soldering akụrụngwa, na okpomọkụ na-eguzogide kwesịrị iru 230 °.Ọ bụrụ na okpomọkụ nke plastic enweghị ike iru ịgbado ọkụ usoro ga-emetụta nkịtị ojiji nke structural deformation.

Njikọ atụdo na-eji plastic akụrụngwa: naịlọn, polyester, naịlọn, elu okpomọkụ - PBT, polyester - PCT, PPS, LCP, na na, dị iche iche liquidity na usoro nke ịkpụzi, plastic ihe eruba ogologo, shrinkage, mmiri imbibition, linear mgbasawanye. ọnụọgụ dị iche iche, na plastic ebu mmepe nwere ọtụtụ ihe na-eme na ihe eji bụ ezi ngụkọta oge.

Oge nzipu: Dec-16-2021